Options available

"Flexible & customized solutions for any wide belt sanding application! All our machines are custom built according to the needs of our customer"

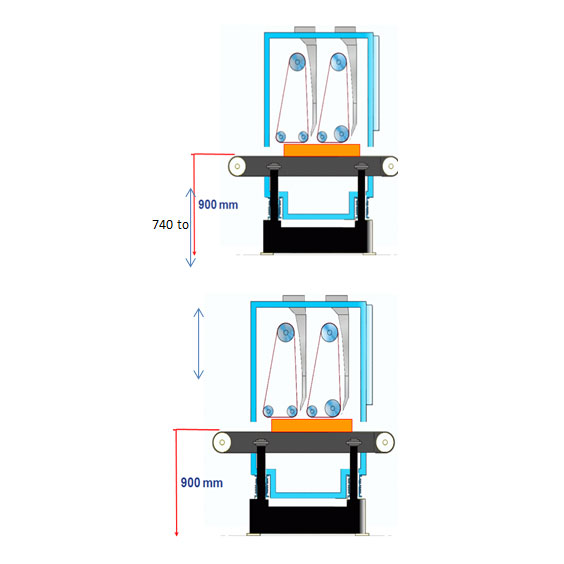

A. FRAME STRUCTURE

Frame Fixed (Stand alone) : Variable height of the feed table from 740 mm to 900 mm. This is the standard version and is ok for small factories were the machine is used as stand alone and not in line with other machines.

Frame Movable (in line machine) : In this case the feed table height is constant at 900 mm and the frame moves up and down to compensate for the work piece thickness. This feature is optional and is required in factories where the machine is used in line with other production / finishing machines and were handling systems like conveyors are used.

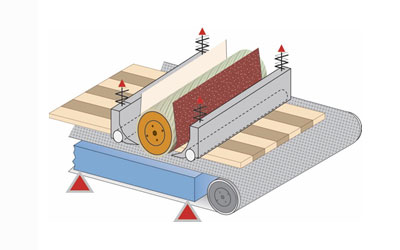

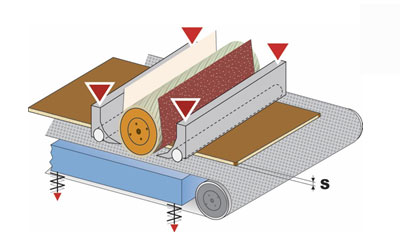

B. FEED TABLE - FLOATING :

IN CALIBRATING MODE : The feed table must be rigid to assure a high level of thickness tolerance of the processed work pieces, while

the pressure units are free to float.

IN SANDING MODE : In veneer / lacquer sanding operation the pressure units are set rigid and the feed table works in a floating mode.

This type of setting allows the levelling of different panel thickness up to a maximum of 2 mm.

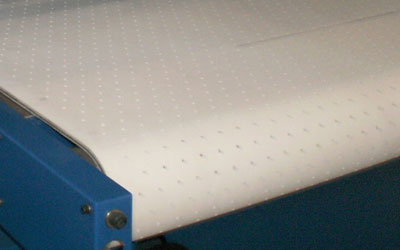

C. FEED BELT :

Rubber feed belts with 3 layers of cloth without joint, for best surface planarity and longer lasting.

Rubber feed belts with 3 layers of cloth without joint, for best surface planarity and longer lasting.

Thick rubber layer on top to allow many re-grinding operations over the years of utilization.

Thick rubber layer on top to allow many re-grinding operations over the years of utilization.

50 / 60 Shore hardness of rubber. Withstand temperature up to 60 to 70°C.

50 / 60 Shore hardness of rubber. Withstand temperature up to 60 to 70°C.

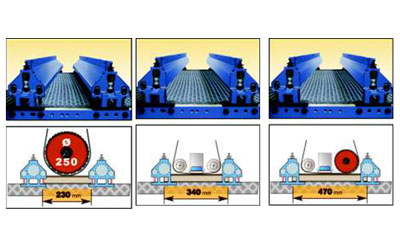

D. CONTACT ROLLERS :

The contact roller can be either rubber covered or steel depending on the application.

The contact roller can be either rubber covered or steel depending on the application.

The hardness of the rubber can be varied from 40 to 90 shore as required depending on the application.

The hardness of the rubber can be varied from 40 to 90 shore as required depending on the application.

E. MOTORS FOR WORKING UNITS :

The motor for working unit is available from 11 kW to 30 kW depending on the type of application.

The motor for working unit is available from 11 kW to 30 kW depending on the type of application.

F. INVERTERS FOR CUTTING SPEED VARIATION :

Inverters are available as an option for cutting speed variation.

Inverters are available as an option for cutting speed variation.

G. ELECTRIAL PANEL :

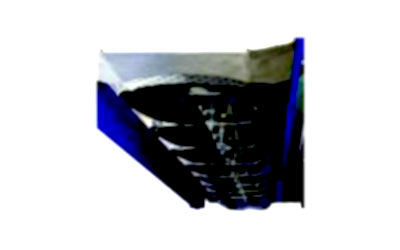

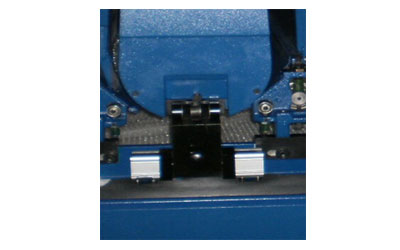

H - Pressure Units :

Proper holding down the work piece is determined by the rigidity of the pressure units; at the same time these units must be able to

adapt to thickness variations that is why the pressure units are linked with springs / pneumatic cylinders to make it rigid or floating

depending on the application – fine sanding or calibration.

I - Panel Cleaning Units :

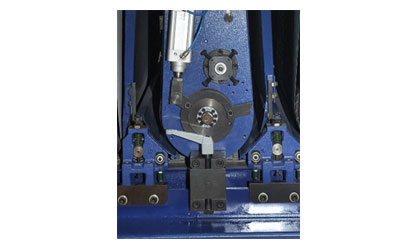

J. Locking of Working Units :

The locking device helps to quickly change the sanding belts and also assuring safe locking of the working unit while in operation

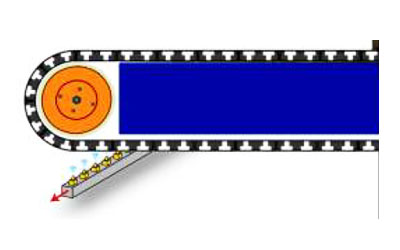

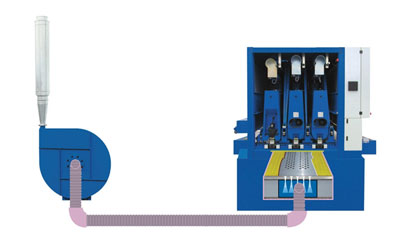

K. Vacuum Hold System :

A high speed ventilator generates a strong pull under each working unit to secure the traction of slippery or short panels.

A high speed ventilator generates a strong pull under each working unit to secure the traction of slippery or short panels.

Vacuum intakes positioned under the working units to diminish the requirement of vacuum-power and to concentrate the

Vacuum intakes positioned under the working units to diminish the requirement of vacuum-power and to concentrate the

vacuum pull only where needed.